Latest News

In Silico and the FDA

The FDA Modernization Act to end animal testing has passed the US Senate. This change nullifies the old mandate requiring animal testing of all new drugs, thereby increasing the acceptance and use of Quantitative Structure-Activity Relationship (QSAR) and read-across (RAX) methods for toxicity testing. In-silico methods reduce the need for animal testing, not only benefitting the animals, but these methods are also more accurate in estimating the toxicity of products/ingredients to humans.

SAXOCON welcomes this focus on enhancing animal well-being while maintaining high standards for determining the safety of chemical compounds. These new methods are the future of toxicological risk assessment, a future we have been at the forefront of for over eight years.

At SAXOCON, we have extensive experience with in-silico toxicity testing and can help you ensure your products are safe and compliant on either side of the Atlantic.

Future-proof your development processes with our cutting-edge modelling and let our experts guide you to the best strategy for using New Approach Methodologies (NAMs).

Contact us for more information.

Read more about our services here:

Medical Devices

Pharmaceuticals

Chemicals

Nitrosamines

Are you a pharmaceutical manufacturer? Do you know whether your products contain nitrosamine impurities and, if so, whether they are below the thresholds established by the various regulatory agencies?

SAXOCON has the expertise and services necessary to help you to fill in the gaps in your supply chain information and assess the impact on your drug substances and products.

Nitrosamines are highly toxic compounds. Some are considered to be even more carcinogenic than currently established thresholds and are subject to strict regulations in both the EU and the US.

Check out how we can help here.

SAXOCON and GARD®

We now offer access to the GARD® technology platform, a second generation of in vitro assays for skin sensitization testing based on genomics and machine learning.

The GARD® technology platform, developed by SenzaGen AB, is intended to gradually replace all animal-based testing components with human equivalents, enabling truly animal-free skin sensitization testing, benefitting animal welfare and human health.

From a regulatory perspective, GARD® skin sensitization testing conforms with ISO 10993 standards and is the first and only non-animal OECD-approved test for assessing the allergenicity of chemicals based on genomics and machine learning.

A better understanding of the biological mechanism that causes skin sensitization has led to significant progress in developing and the regulatory implementation of New Approach Methodologies (NAMs) for this endpoint. These methodologies include computational models and cell/tissue in vitro-based assays. In addition to not testing on living animals, NAMs also have the benefit of generating more human-relevant information.

At its core, the GARD® technology platform uses an analysis of a human cell’s total response when exposed to different substances and has four key elements:

- a biological cell system based on a human dendritic-like cell line, mimicking critical parts of the immune system and recognizing allergens

- a dataset for biomarker discovery and subsequent machine learning training

- a gene expression pattern to establish a genomic biomarker signature

- a prediction model to perform future classification of the test chemicals

These four elements are key to improved accuracy and human relevance, as they combine the simplicity of in vitro methods and the biological intricacy of in vivo models.

Find out how we can help you here.

MDR and Biological Safety

Complying with EU Medical Device Regulation (MDR) is not optional. If you are a manufacturer, authorised representative or distributor of medical devices, you will need to ensure compliance with EU MDR.

Non-compliance with biological safety requirements can result in costly delays when designing, developing or selling a medical device. SAXOCON provides you with everything you need to plan, test, and document compliance with regulatory requirements and ensure the biological safety of your medical device products.

The General Safety and Performance Requirements (GSPR) checklist is a mandatory document all medical device manufacturers must complete prior to an MDR audit. SAXOCON has the expertise to help you comply with paragraphs 10 and 11 from CHAPTER II, REQUIREMENTS REGARDING DESIGN AND MANUFACTURE, of this checklist.

Putting processes into place that ensure quality and safety throughout your supply chain allows you to confidently engage with notified bodies, knowing that you are in compliance or can easily become compliant with the (EC) 2017/745 (MDR) regulation.

SAXOCON is ISO 13485 certified, which means that we can serve as an approved critical supplier and help you minimise the headaches associated with regulatory compliance.

Read more about how we can help you here.

Congrats to the 2022 Danish Tech Challenge Participants

As a member of the DTU family, we would like to congratulate the 19 participants in the 2022 Danish Tech Challenge, Denmark’s leading accelerator for hardware start-ups, at the DTU Science Park Futurebox incubator.

At SAXOCON, we specialise in in-silico toxicological testing, risk assessment, and regulatory documentation for pharmaceutical products and medical devices.

Check out what we can do for you here, or contact us directly at moc.nocoxas@selas for more information.

On-site Aerosol Sampling

Exposure to aerosols can negatively affect health.

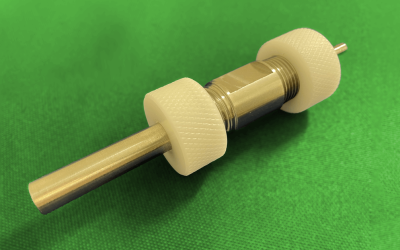

Using our SAXOCON Impactor tool, we can determine what is in the air at your workplace, if there are any risks, and how to mitigate potential problems.

We designed and built the SAXOCON Impactor to be a highly efficient, multi-stage impactor that collects airborne particles (down to the nanoscale) for analysis.

Our impactor is intended for on-site use and quickly collects the necessary samples. After collection, you return the impactor to us for an analysis of the collected particles to determine the distribution and concentration of sizes, whereafter our toxicologists establish their level of toxicity.

Gain some understanding about what is in the air you breathe and how it affects workplace safety.

Read more about how we can help you here.

GAeF Membership

Our CSO, Kirsten Inga Kling, has joined GAeF (Gesellschaft für Aerosolforschung e.V.) as a supporting member. We look forward to contributing to the discussion, learning, and sharing knowledge with other experts in aerosol research.

Check out our analytics services here.

Celebrating Arla’s BLG Novel Food Application Success

SAXOCON congratulates Arla Foods Ingredients on the positive EFSA opinion regarding their novel food application for Lacroprodan® BLG-100. We are proud that our contribution helped get the application over the finish line and look forward to Arla receiving full EU approval for BLG later this year.

Read more about Arla Foods Ingredients’ announcement here.

If you are developing a novel food and need help to ensure compliance with EU and FDA requirements, check out how SAXOCON can help you here.

FDA CGMP Requirements Incorporating ISO 13485

We are on the verge to merge. Things in the regulatory space for medical device manufacturers are about to get easier.

In a new proposal on Quality System Regulation Amendments for Medical Devices, The FDA has decided to harmonize their GMP requirement for medical devices by incorporating the QMS requirements from ISO 13485.

This harmonization will ease the regulatory burden on medical device manufacturers selling on both sides of the Atlantic. Medical Device Manufacturers and their suppliers and subcontractors that are ISO 13485 certified will no longer have to comply with a different set of standards for approval in the USA.

SAXOCON is ISO 13485 certified and can help you with your QMS, which helps you comply with all relevant regulations but also gives you a better understanding of your supply chain and manufacturing processes.

Read more about how we can help you here.

Food Contact Materials Biosafety

Packaging is not the first thing we think of when we think of food. However, the biosafety of the materials used in food packaging impact the food contained within. So, it is essential to understand the health and safety consequences of the packaging. For more information, read this EFSA article on food contact materials regulations.

All food packaging materials, known as food contact materials, must be evaluated for their potential for transferring harmful substances to food. Every supplier in the supply chain for food contact materials is responsible for demonstrating compliance with all applicable rules and regulations regarding food contact materials.

SAXOCON can help you ensure that your materials comply with EU and FDA rules concerning food contact materials.

Check out how we can help here.

Biosafety and In-Vitro Diagnostics

Do you manufacture in-vitro diagnostic medical devices?

If so, you will need a CE Mark certificate to market them in the EU. A CE certificate verifies the biosafety of your products and that they perform as intended. Regulations such as (EU) 2017/746 (IVDR) Annex I set general biosafety and performance requirements for designing and verifying in-vitro diagnostic medical devices. Our experts have the knowledge and experience to help you plan, test, and document compliance with all regulatory requirements and get your product to market.

Check out how we can help here.

Material Readiness and Marketability

To know your materials is the beginning of wisdom.

One key aspect of manufacturing is materials screening. Proper biosafety and sourcing require having full transparency about the physical and chemical information associated with your materials throughout your supply chain to help mitigate risk, reduce unexpected events, and keep regulators happy.

Manufacturers of medical devices, pharmaceuticals or combination products operating in the EU must ensure the quality and safety of the materials used in their products before marketing them. Early and robust materials selection helps meet regulatory requirements, mitigate risk, and get your products to market quickly.

Check out how we can help here, here, here, here, and here.