Latest News

Stay Compliant with ECHA Regulations

The substances of very high concern (SVHC) candidate list is constantly changing. In a recent update, eight new substances, widely used in consumer products such as cosmetics, scented articles, rubber, and textiles, were added to the candidate list for restriction in the EU because they are hazardous to human health. All suppliers of physical products in the EU market must track and report any SVHCs found in their products. This information shall be made available to consumers and waste operators by filling in the Substance of Concern in Products (SCIP) with the European Chemical Agency (ECHA).

SAXOCON can help you comply with your obligations regarding tracking your supply chain, evaluating potential SVHC, and submitting your information to ECHA.

Are Airborne Ultra-fine Particles Toxic?

Do you know what airborne particles you are exposed to and which of these particles is a health concern?

We can help you determine what is in the air you are breathing, the risks posed, and how to mitigate potential problems.

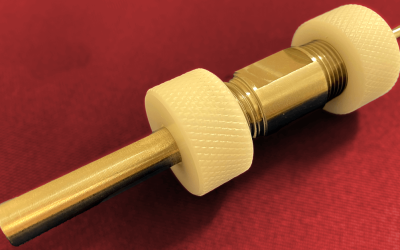

Using the method improved at DTU Nanolab, SAXOCON has designed and built a highly efficient, multi-stage impactor that collects airborne particles (down to the nanoscale) for analysis.

Check out DTU Nanolab’s article about their method here.

Our analysis of the collected particles not only quantifies their size distribution and concentration but also determines their level of toxicity.

Gain some peace of mind and find out what is happening with your air quality.

Read more about our services here.

EU no Longer Considers Titanium Dioxide Safe as Food Additive

Titanium dioxide is widely used in the EU as food colourant E171. In May, EFSA announced that titanium dioxide is no longer considered safe when used as a food additive. Recently, a similar concern has been expressed concerning its use as an additive in animal feed. The result of these findings and concerns is that an Acceptable Daily Intake (ADI) for titanium dioxide can no longer be established. If you use E171 in food or animal feed, you will need to update your product risk assessment.

EFSA news on titanium dioxide as a food additive.

EFSA news on titanium dioxide as an animal feed additive.

We can help you stay up-to-date with regulatory changes. SAXOCON provides services to monitor and assess product risk in relation to current regulations.

Read more about our food industry services here.

Is Your Biological Evaluation Supplier ISO 13485 Certified?

Are you a medical device manufacturer?

According to the new Regulation (EC) 2017/745 on medical devices (MDR), medical device manufacturers must demonstrate to notified bodies that all critical suppliers conform with the ISO 13485 standard covering quality management systems.

As a critical supplier of high-quality toxicological services, SAXOCON is ISO 13485 certified, which means that there will be one less thing to worry about at the next audit.

Having confidence in your suppliers allows you to focus on your manufacturing processes and get your products approved and ready for market as quickly as possible.

Find out how we can help you here.

Partikler i dit arbejdsmiljø

Er du den arbejdsmiljøansvarlige hos jer? Har I et værksted, en produktion eller et laboratorie? Og ved du, hvad der er i den luft, I indånder?

Der findes mange arbejdsprocesser, hvor der kan opstå fine og ultrafine partikler, som kan være farlige for jeres helbred.

Hos SAXOCON har vi den nødvendige ekspertise og erfaring til hurtigt at vurdere og løse problemer med uren luft i dit arbejdsmiljø.

Læs hvordan SAXOCON kan hjælpe jer her.

SAXOCON CTO at 2021 Cleaning Validation Conference

SAXOCON is pleased to announce that our CTO, Carsten B. Senholt, will present at the 3rd Cleaning Validation LIVE event on 3 June 2021 at 13:40.

Carsten will introduce the basic principles behind establishing Permitted Daily Exposure (PDE) and its role in supporting cleaning validation in shared facilities.

Find out more about the conference here.

SAXOCON is now ISO 13485:2016 Certified

After more than a year of dedicated effort and nearly 4.000 hours of preparation, we are proud to announce that we have received the globally recognised ISO 13485:2016 certification from BSI under certificate number MD725842.

We chose BSI as our certification partner because they are a well-known and respected provider of certification services and act as an EU notified body for medical devices under MDR/IVDR.

Being a toxicological consultancy company makes us one of only a select few that have obtained this certification.

Achieving ISO 13485:2016 certification is a major strategic milestone in providing our clients with state-of-the-art toxicological and biological safety consultancy services within a quality management context.

SAXOCON is a high-risk supplier for many of our clients and, as such, being ISO certified proves that our consultancy services are built on a foundation of quality processes, encompassing all stages of the value chain from design to final delivery.

We’re just getting started

Obtaining this certificate is not a one-off event. To continue being ISO certified, BSI will audit us on an annual basis. We have committed ourselves to continually investing in the development and improvement of our quality management system.

If you are interested in learning more about how our quality management system can support your business, please do not hesitate to reach out.

New Partners at SAXOCON

We are so very pleased to announce the addition of three new partners. Our highly skilled and valued colleagues Carsten B. Senholt, Kirsten Kling, and Martin Hover are now partners at SAXOCON. This happy news is also an important step in our development as a business.

So, three cheers for our three new partners.

Unexpected Findings

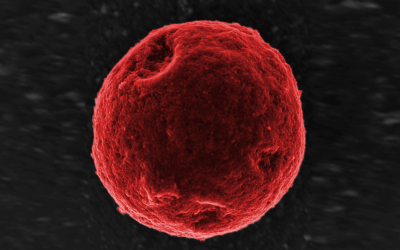

Are you responsible for the production of pharmaceutical products such as vaccines? What if you suddenly find something unexpected? What if there is some foreign material or particles in one of the vials in your production?

Sudden unexpected findings of particulate matter in or in contact with drug products are common in pharmaceutical production facilities. Good Manufacturing Practice (GMP) and proper risk management of product quality require identifying the root cause and evaluating the impact of findings on product safety. This knowledge is crucial to deciding whether to release or recall affected product batches.

A quick response is necessary when such a finding occurs. Production must be put on hold while the affected lots are identified, and then the hard work of figuring out the type and extent of the problem begins.

SAXOCON has the in-house expertise and experience to quickly assess, process, and help mitigate any unexpected findings.

Check out how SAXOCON can help you here.

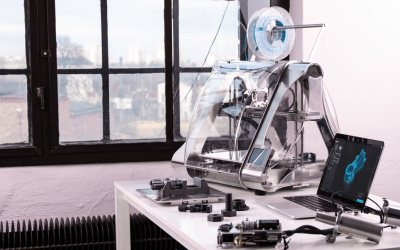

3D Printing and Your Health

Are you using 3D printers to produce mock-ups or in manufacturing? What kind and how many particles are produced while using a 3D printer? Particles produced during 3D printing pose a health risk. In fact, they are almost as harmful as the exhaust produced by Diesel motors. Ensuring good air quality and the health and safety of your workplace requires knowing what is in the air you are breathing.

Current rules and regulations for determining air quality use particle mass for determining what level of pollution is acceptable. In fact, the toxicity of a particle is determined by a variety of attributes other than mass. Additionally, the number of particles in a given space plays a role in your exposure. This determines how many particles end up inside you and what the consequences are for your health.

SAXOCON can assess your workspace design on-site, identify sources and measure particle concentrations.

Check out how we can help here.

Food Contact Materials

Packaging is not the first thing we think of when we think of food. However, the materials used in food packaging impact the food contained within. So, it is essential to understand the health and safety consequences presented by the food packaging used.

Any materials used for food packaging, known as food contact materials, must be evaluated for their potential for transferring harmful substances to food. Every supplier in the supply chain for food contact materials is responsible for demonstrating compliance with all applicable rules and regulations regarding food contact materials.

SAXOCON can help you ensure that your materials comply with EU and FDA rules concerning food contact materials.

Check out how we can help here.

Happy Easter! ![]()

![]()

Get Ready for EU MDR

The deadline, 26 May 2021, for EU MDR is fast approaching.

The Danish Medicines Agency (Lægemiddelstyrelsen) recently published guidance regarding the new regulations and their consequences for both industry and Danish authorities. Read their guidance here (Danish only).

Keep abreast of the latest news and information regarding MDR and make sure your products are ready for the new regulations. SAXOCON can help you to ensure your products are qualified.

Are you ready? We are.

Check out how we can help here.